SAP Extended Warehouse Management

SAP Extended Warehouse Management optimizes warehouse operations, from inventory tracking to resource management. With features designed for scalability and integration, SAP Extended Warehouse Management enables businesses to efficiently manage highvolume warehouses.

Enhance your warehouse operations with SAP EWM, empowering your facility with intelligent solutions to boost efficiency, ensure material traceability and lower costs.

What is SAP Extended Warehouse Management?

“DOES MY ORGANIZATION NEED SAP EWM”?

FAQs

Your Guide to SAP Extended Warehouse Management

SAP EWM, next generation WMS system from SAP is built for this specific purpose.

SAP EWM is perfect solution to track and maintain inventory with precise bin locations.

Unlock the potential of real-time visibility by effortlessly tracking inventory levels, order statuses, and resource utilization with warehouse KPI’s and EWM.

With SAP EWM, embrace the seamless integration with web services and RF devices for all warehouse execution which gives you full control of your business process.

Well say goodbye to those problems with SAP EWM It will keep track of all inventory discrepancies and will give you real-time and historic insights of inventory.

SAP EWM optimizes resource allocation, allowing you to accomplish more with fewer resources.

Well, all those got covered with SAP EWM yard management and dock appointment scheduling integration.

IF YOU ANSWERED 'YES' TO ANY OF THESE QUESTIONS, SAP EWM holds the key to your organization's success. Contact our team of experts today to unleash the true potential of your business.

SAP EWM, next generation WMS system from SAP is built for this specific purpose.

SAP EWM is perfect solution to track and maintain inventory with precise bin locations.

Unlock the potential of real-time visibility by effortlessly tracking inventory levels, order statuses, and resource utilization with warehouse KPI’s and EWM.

With SAP EWM, embrace the seamless integration with web services and RF devices for all warehouse execution which gives you full control of your business process.

Well say goodbye to those problems with SAP EWM It will keep track of all inventory discrepancies and will give you real-time and historic insights of inventory.

SAP EWM optimizes resource allocation, allowing you to accomplish more with fewer resources.

Well, all those got covered with SAP EWM yard management and dock appointment scheduling integration.

IF YOU ANSWERED 'YES' TO ANY OF THESE QUESTIONS, SAP EWM holds the key to your organization's success. Contact our team of experts today to unleash the true potential of your business.

SAP EWM standard offerings?

Inbound process:

Outbound process:

Inventory Management:

Warehouse Structure:

Warehouse Task Management:

Resource Management:

Seamless integration with S/4HANA core modules and some advance module like TM, GTS, YL, etc.

Know more about our SAP consulting services

Warehouse order creation rules

Storage control:

Physical inventory:

Replenishment:

Cross-Docking:

Wave management:

Key Features

Real-Time Inventory Management

Task Interleaving

Wave and Slot

Management

Labor Management

Advance EWM Offerings

direct dispatch including additional services like kitting and labeling

Value added services:

Yard Management:

Labor Management:

Cartonization Planning:

MFS:

Integrations and connectivity:

Reporting and Analytics:

Benefits

Reduced Costs

Improved Accuracy

Enhanced Customer Satisfaction

What Benefits customers achieved after implementing EWM?

Improved Inventory Visibility and Accuracy

Increased efficiency and productivity

Reduced Costs

Enhanced Customer Service

Better Supply Chain Visibility

Scalability and Flexibility

Flexible reporting and Analytics

Improved space utilization

Reduced process errors

Seamless integrations

SAP EWM Integration with internal and external system?

- AGV & AMR Integration with SAP EWM.

- ASRS Integration with EWM.

- MES Integration with EWM.

- Integration of SAP EWM with cross SAP modules like TM, GTS, YL.

- Integration of SAP S/4HANA with SAP EWM.

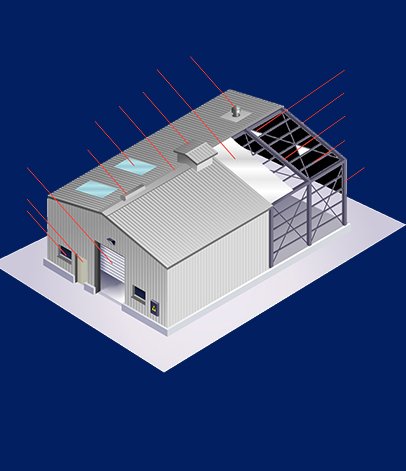

SAP Implementation methodology

Use Cases

High-volume retail warehouses requiring advanced picking and packing strategies.

Temperature-controlled inventory management in pharmaceutical distribution

Multi-location warehouse networks for global manufacturers.

Integration

Target Audience